A Digital Twin For Process Operations

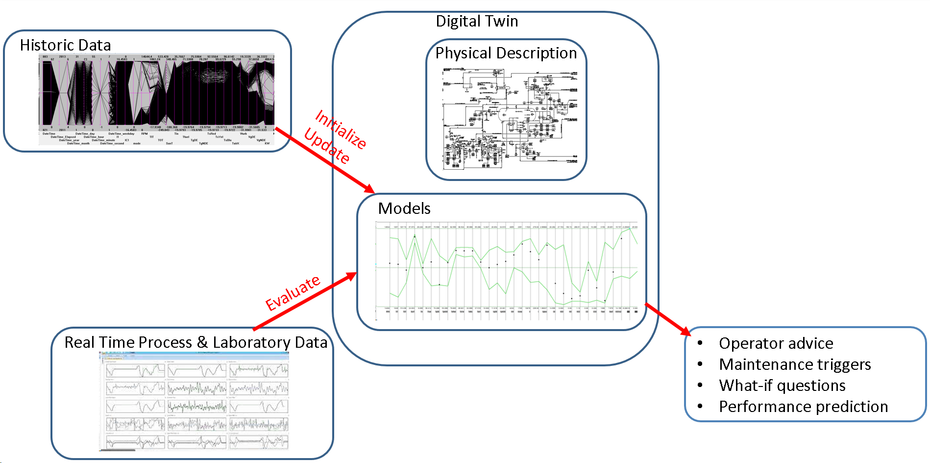

If you don’t already have a real-time first-principles model of your process you can either spend a lot of time and money to build one, or with PPCL’s geometry-based methods, you can use the knowledge of how your process “runs best” that is buried in your process history to directly advise your operators.

Our models more faithfully represent your process (continuous, batch, grade transition and time-varying) for real-time use than any first-principles or physics-based model can.

“Runs Best” means the model achieves all your Lagging KPI’s by capturing how you achieved them in the past using CVE. You extract this Envelope and reset the Operating Limits on the process variables and Leading KPI’s as many CVE-users are doing already for off-line optimization, alarm rationalization and condition monitoring. CPM then creates a real-time model of this new Operating Envelope complete with Operator Display and OPC Clients to connect to your DCS and/or process historian.

Open-loop Operator guidance starts from much more accurate Consistent Alarm Limits moving into dynamic model-based Operator Alerts. This change can be done in stages, providing a smooth and painless transition. The combination of Alerts and Alarms guides operators to keep the process operating at its best and provide Condition Monitoring with very long warning times of equipment changing its behaviour as well as approaching avoidable process conditions such as column flooding or compressor surge.

Processes change capability over time and there is a three-way dependency between operating objectives, operating procedures and process capability so that when one of them changes at least one of the other two needs to change as well. This can be seen by monitoring the model and addressed by integrating the new behaviour into the model as necessary to maintain consistency.

Who Builds these GPC Models?

Your existing process and control engineers after training and coaching from PPCL. Experienced users say they can develop and commission a new model in a day because thanks to the inherently visual nature of geometry there are no equations to formulate and solve and no heavy maths – we build working models from scratch during webinars so you can see for yourself just how straightforward it is.

The knowledge you will need is good understanding of the process, its operating procedures and actual operating practices that Unit process engineers and control engineers possess.

And it all operates on low-cost Windows PCs on IT and/or OT networks!