Are your process problems getting out of control?

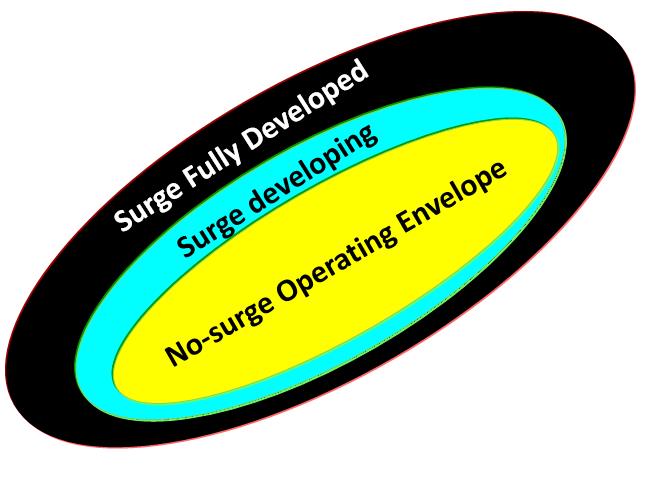

Event Prediction and Mitigation includes undesirable events such as column flooding, compressor surge, film breaks and plant trips which occur repeatedly in most processes. This is often because process efficiency is at a maximum just before these events occur, thus providing constant temptation to operate as near as possible to an unknown invisible boundary without crossing it. To make it more complicated, the boundary is not fixed but moves under the effects of both external and process variables.

Depending on the industry sector process operators and engineers have either allowed a generous safety margin around where they think the invisible boundary could be and accepted the cost of lower process efficiency or have become expert at quickly recovering from the event after it has occurred thus reducing the cost of the disturbance on the rest of the process.

Geometric Process Control’s real-time models of operating envelopes created from past event occurrences have proven to be very sensitive multi-variable detectors of imminent event occurrence able to give operators warning with sufficient time to allow them to mitigate or avoid the event entirely by making small setpoint alterations. This allows operation closer to the event boundary and thus at higher process efficiency.

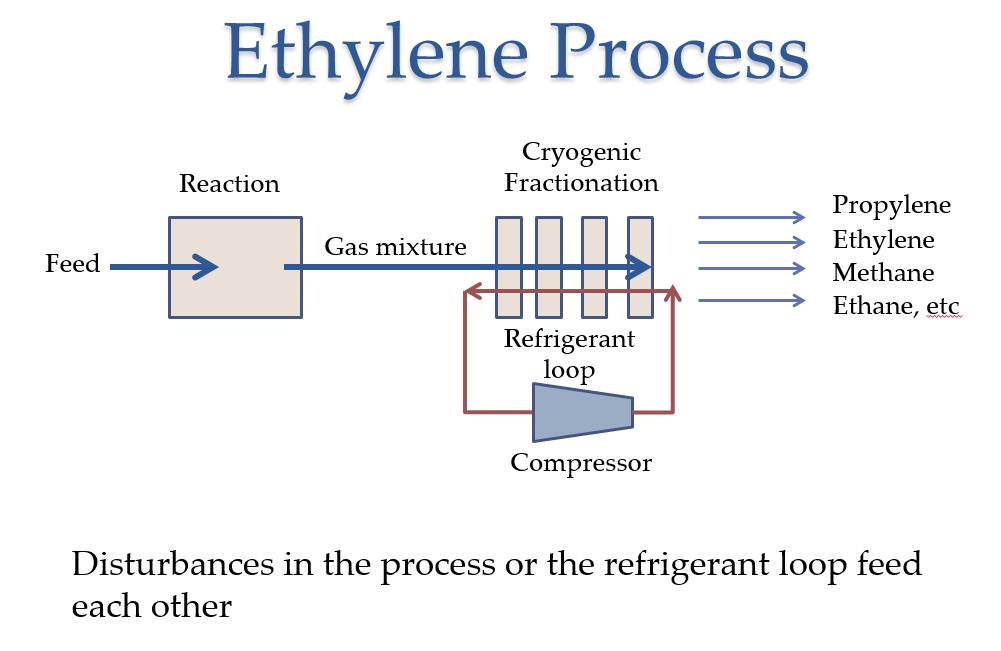

An example is the very large multi-stage refrigeration compressor in an ethylene process:

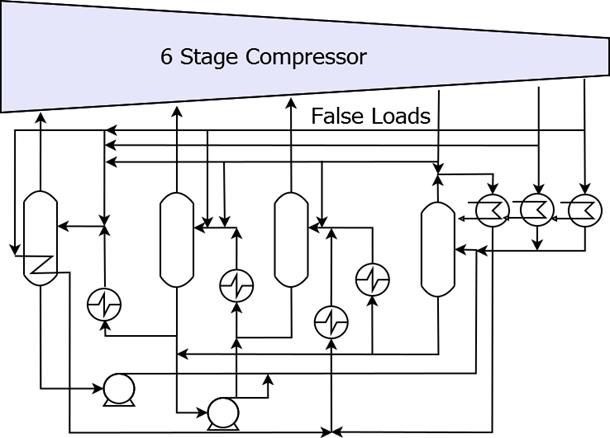

There are inter-coolers between stages to remove the heat generated by compression which leads to each stage having side-feeds and offtakes so that a stage may go into surge independently of the other stages. Surge is the lack of sufficient mass flow through a stage and can be very damaging, so there is a very sophisticated automatic surge protection system which operates immediately surge is detected by opening valves that feed gas from the output back into the inlet of a stage or stages to correct the mass flow shortfall.

The refrigeration system is driven by the demand for “cold” from the cryogenic multi-column distillation process that separates the mixture of gases coming from the ethylene reactors into its component gases. If insufficient “cold” is delivered by the refrigeration system then the process controls adjust column operations to match supply and reduce demand, but these alterations can take several minutes to take effect and propagate through the series of columns, during which time the refrigeration system has corrected for the earlier shortfall so is now providing more “cold” than was requested triggering further adjustment of the process before the consequences of the previous adjustment have had time to settle out. Disturbed process operation can persist for several hours following activation of the compressor’s surge protection system. This has a high cost, but operating at maximum compressor efficiency close to surge has a high value.

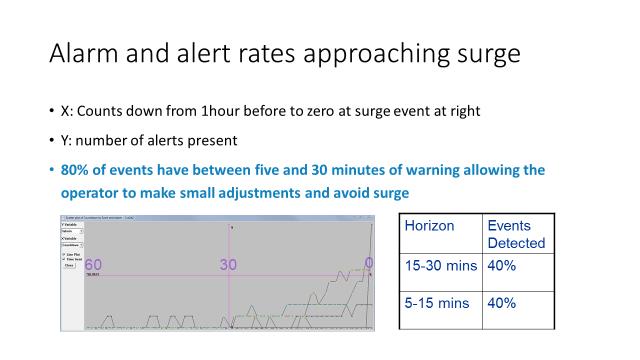

C Visual Explorer (CVE) was used to extract 23 past surge events from several years of process history and to create a count-down time so that each surge event (the anti-surge valves opening) occurred when the countdown reached zero. This allowed all the events to be aligned so that by experimentation in CVE we could find a reasonable duration before surge for the blue incipient surge period.

A high-speed replay of the lead-in to one surge event is below. Normal speed would be one or two updates per minute for most applications.

But more important are the prediction results achieved. 80% of these 23 past surge events would have been predicted at least 5 minutes before they occurred and could have been avoided by operator action. Some of the remaining 20% were predicted during the last 5 minutes when it is less certain that operator action could have avoided all of them. Further CVE investigation of these low-alert events that still led to surge can continue while savings are garnered from eliminating the initial 80% of the readily detectable (using GPC) surge events.

Event Prediction models will detect other events causing an increase in alerts such as developing equipment faults, although these would be expected to be much less frequent than process events. The pattern of alerts is likely to be different and examples have been seen in process history of equipment faults such as sticking dampers being alerted days before the fault developed sufficiently to necessitate a shutdown for repair. Process operators need to be trained to react to unusual patterns of alerts and seek assistance in diagnosing possible cause.

Once familiar with the use of CVE and CPM models such as this, an engineer can re-build and commission a model in 2-3 hours to incorporate new process history data reflecting increased understanding of, for instance, the low-alerting events above that were not detectable until the final five minutes before surge. The initial model creation will always take longer because of upfront time spent in CVE analysis to understand the problems and causes.