The root-cause of Alarm Rationalisation having been such a tedious and time-consuming procedure has been the lack of any capability for Alarm Performance Prediction (APP). You have had to choose values for alarm limits and then implement and use them in the control room for days or weeks before knowing whether you chose the right value. With hundreds of alarm limits to manage the cycle of monitoring, adjusting, reviewing and re-implementing activity alone represented a substantial workload that in practice was rarely adequately resourced. Being able to predict alarm performance before implementation would eliminate most of this activity and free-up resources for more effective process stewardship.

You can’t do Alarm Performance Prediction with the alarm log data that is the basis of most of todays alarm management systems because it doesn’t contain sufficient information about process behaviour. But you can do it with PPCL’s CVE product using the process history data that you already have in your process historian database (eg. PI, PHD, IP21 and many others). It is often useful to use other performance history data that you already have in laboratory, vibration, corrosion, environmental compliance and many other KPI databases.

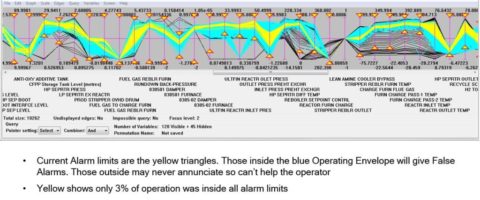

Almost all the problems of operator alarm systems start (and can be ended) with the values you assign to the operator alarm limits. There was little guidance and no method for finding these values in the past. EEMUA 191 and ISA SP18.2 both give very general guidance to “position the operator alarms around the boundary of where you normally operate” but with no advice on how to locate that boundary for every alarmed process variable.

Our Operating Envelope- based method implemented in CVE is very fast and easy to apply and shows you “the boundary of where you normally operate” within minutes. CVE provides Alarm Performance Prediction so that you can set your alarm limit values to be ‘right-first-time’ when you put them into use.

Once you have positioned alarms correctly (and you should only need to do this once unless you make major process changes) you will have eliminated the majority of false alarms. This alone will, over time, substantially increase the operators belief in the few alarms that remain so that requested alarm actions will be made sooner and you will see an improvement in process performance as a result.

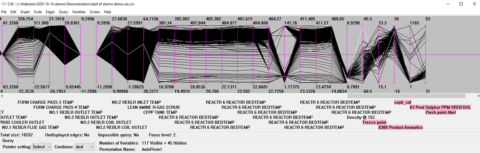

You will learn a great deal about your process and its strengths and weaknesses just from seeing the inter-relationship of operating limits, MPC constraints, operator alarm limits, pre-trip limits, trip-limits and safety limits all in one picture for hundreds of process variables. This is valuable as a one-time exercise but much more valuable when performed on a regular basis as a Process Stewardship activity where it contributes to operating your plant at its best efficiency for more of the time than you do today.

Process Stewardship using the multi-variable views provided by CVE will show, for instance, where further control and/or operating improvements could be made. The same CVE view will also show where previous improvements have been successful so that operator alarm limits could be ‘tightened’ to capture the improvement and prevent regression to the earlier less effective operation. Process Stewardship is usually a process engineering activity led by the unit process engineer and preferably including the whole operations team for review and implementation. Our product development concentrates on meeting the needs of both time-constrained engineers and ease of understanding for operations.

Control engineers will appreciate the help that CVE provides in optimising MPC constraints and in allowing them to predict the alarm performance of state-based and Mode-based alarm settings for effectiveness in managing both alarm floods and the long periods of process disturbance that often follow an alarm flood. Advanced applications may benefit from the use of the companion CPM product which provides real-time operating envelopes for the implementation of Predictive Alarming.

How can you find out more? There are articles elsewhere on this website but the best way is to attend a New Alarm Rationalisation webinar. You will find a link to our webinar schedule on the home page and can enrol from there too. And if our schedule doesn’t match your needs then call or email and we will be happy to look at alternatives with you.