Discover How To Run Intelligent Process Plant Operations

Empowering process & control engineers with the most powerful interrogation and visualisation technologies to intelligently solve their most complex challenges:

- Improve Plant Safety

- Increase Batch Consistency

- Reduce Emissions

- Increase Profitability

Process Plant Challenges

Alarm Limits

How do you reduce false alarms displaying throughout your manufacturing process? How do you properly position alarm limits to increase safety, efficiency and throughput whilst reducing operator costs?

Reducing Downtime

How are you identifying the frequency of events that lead to downtime? Do you have the best early warning detection for your operators? Are you making informed changes to your process to reduce the frequency of downtime?

Running Costs

Can you identify methods of improving the overall performance of your organization's production that will reduce the energy consumption and your overall expenses? How do you monitor live data to identify early warnings?

Plant Maintenance

Not being able to predict plant maintenance issues can be very expensive. Do you have early warnings in place to plan preventive maintenance?

Energy Reduction

With global pressures to meet lower emissions targets and significantly increasing energy prices, do you know how to use your plant historian data to quickly and effectively reduce your process energy usage?

Product Quality

Maintaining high product quality standards is a constant challenge. How do you detect a manufacturing process starting to deviate from the golden batch envelope?

Accelerate Your Digital Transformation

You Can't Afford To Wait

When your plant needs are complex, the solutions can be overwhelming.

Our software will get you the roadmap you need:

01

Assess Your Plant Historian

Starting with your organization's existing plant historian, we can identify the optimal next steps to improve your most challenging issues.

02

Optimise & develop an intelligent operating envelope for all your production lines

Our experts can work with your engineers to explore and interrogate large datasets, meet with your subject matter experts and engineers to teach practices to visualise real-time process modelling, create operating envelopes and optimise your plant’s transformation processes.

03

Harness all the benefits of our modern technology

Utilise the power of CVE & CPM and see how your plant harnesses the power of this unique technology to meet KPI's, increase efficiency and improve plant safety.

The Most Powerful Interrogation & Visualisation Technology

Our two software tools. CVE & CPM, combine unique powerful technologies, to offer industry-leading interrogation tools for subject experts to fulfil their insatiable curiosity across process plant operations and visualise real-time process modelling to predict & manage future plant performance.

C Visual Explorer

Generate insight from past performance to better understand & improve your process

C Process Modeller

Real-time process modelling to predict & manage future performance

Discover how to run optimised intelligent

process plant operations:

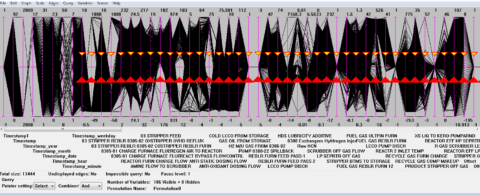

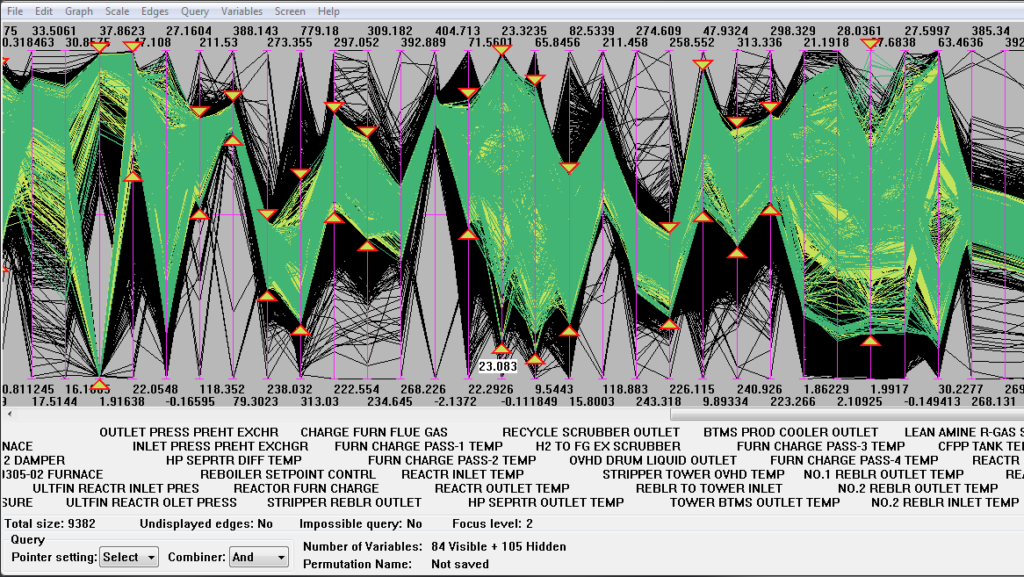

Analyze

Explore, Interrogate and identify areas of improvement from your plant's past performance. See your entire plant process in one visualization tool. What makes CVE unique is the thousands of variants from multiple datasets brought together to be analysed at the same time. With advanced filtering options, you can discover new insights and patterns that can truly make a difference.

Improve

Once you identify actionable improvements in your process, you can begin optimising your operating envelope and set new alarm limits. Using CVE to visualize each and every part of the production process, enables actionable behaviours or small corrections to be made at all levels of the plant.

Monitor

Get real-time alerts through CPM to keep your process in-line. The software monitors your process 24/7 and visually updates all operating variables within our visualisation tool to alert and prevent production issues. Control engineers have access to a display that tells, at a glance, whether the process is under control and operating within set operating envelopes. In alarm systems, CPM generates alerts that have the objective of keeping the process inside the fixed HiLo Alarm Limits found by CVE, allowing an increased level of process safety.

Control

Manage your plants ongoing performance with full operational insights by combining CVE & CPM. Utilising these powerful technologies on a daily basis, allows control engineers to run intelligent operations that maximise performance output, meet many KPI's and minimise safety risks. As the digitization of process plant continues, PPCL offer solutions and techniques that enable true data-driven decisions for improving all areas of your plant's production.

Ready To Get Started?

1 - Book A Demo

2 - Build Intelligent Operating Envelopes

3 - Gain New Process Improvements

Versatile Software For Many Processing industries

We have products transforming process plant operations worldwide in a large number of industries:

Oil & Gas Refineries

Petro Chemical Plants

Power Generation

Pharmaceutical

Food & Beverage

Minerals Processing

Pulp & Paper

Mining & Metals

Water & Wastewater

Selection Of Our Customers

What Sets PPCL Apart?

Specialized Support

With decades of experience in Process Plant operations, our team know how to help.

Reliable

Purpose built offline software tools with a strong reputation for reliability. Our tools have over two decades of research & development.

Fast & Secure

Quickly compile, enhance, and deliver high-volume, high-fidelity, real-time data within your secure networks.

Backed By Experts

Experienced Chemical engineers helping enterprises achieve operational insights.

Are your process problems getting

out of control?

PPCL Consulting Services can come to you, investigate your process and give you the information you

need to get things back on track and in line with business objectives.

Testimonials

Webinar Replays:

On Demand Webinars

All the latest PPCL webinars are available to watch at your convenience.

Discover The Latest News & Resources

Check out the latest news, blogs, events and success stories.

Let's Work Together

We’ve been delivering process plant software solutions for nearly 30 years. Why not book a demo and see for yourself how CVE & CPM can transform your process plant.